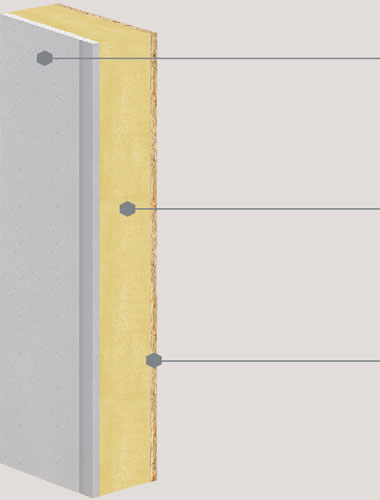

OSB-Wooden Ready Wall

- Eps Hazır Duvar

- Poliüretan Hazır Duvar

- Taşyünü Hazır Duvar

- Tek Yön Alçıpan (Eps)

- Tek Yön Alçıpan (Poliüretan)

OUR OSB-WOOD READYMADE WALLS (EPS-INSULATED)

• EPS Polystyrene is in the B2 fire class.

• Its heat conductivity value is 0.033 w/mK.(It depends on thickness of the core.)

• TSE-825 use temperature is between -50 ºC and 75 ºC.

• Densities 16, 18, 20, 24, 26, 28, 30 kg/m³

• Thicknesses of the insulation core (filler): 20 mm. 30 mm. 40 mm. 50 mm. 60 mm. 80 mm. 100 mm. 120 mm. 150 mm.

• Coating Thicknesses (shells): 8 mm. 9 mm. 10 mm. 11 mm. 15 mm. 18 mm. wooden panels like Osb, Plywood etc.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* (OSB) WOOD

INSULATION PRODUCTS

* EPS

EXTERIOR SURFACE PRODUCTS

*(OSB) WOOD

*FIBERCEMENT

*MAGNESIUM OXIDE

*PLASTERBOARD

OUR OSB-WOOD READYMADE WALLS (POLYURETHANE-INSULATED)

• Polyurethane is in the B2 fire class.

• Its heat conductivity value is 0.022 w/mK. (It depends on thickness of

the core.)

• TSE-825 use temperature is between -50 ºC and 75 ºC.

• Densities 38-40 kg/m³

• Thicknesses of the insulation core (filler): 20 mm. 30 mm. 40 mm.

50 mm. 60 mm. 80 mm. 100 mm. 120 mm. 150 mm.

• Coating Thicknesses (shells): 8 mm. 9 mm. 10 mm. 11 mm. 15 mm. 18 mm. wooden panels like Osb, Plywood etc.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* (OSB) WOOD

INSULATION PRODUCTS

* POLYURETHANE

EXTERIOR SURFACE COATINGS

*(OSB) WOOD

*FIBERCEMENT

*MAGNESIUM OXIDE

*PLASTERBOARD

OUR OSB-WOOD READYMADE WALLS (ROCKWOOL-INSULATED)

• Rockwool is used with the purpose of heat-sound insulation and fire insulation.

• Its heat conductivity value is 0.040 w/mK. (It depends on thickness of the core.)

• TSE-825 use temperature is between -50 ºC and +750 ºC.

• According to the German Norm DIN 4102 u TSEN 13501-1, it has the A Class incombustibility.

• Densities 40-50-75-80-100-110-150 kg/m³

• Thicknesses of the insulation core (filler): 50 mm. 60 mm. 80 mm. 100 mm. 120 mm. 140 mm. 150 mm.

• Coating Thicknesses (shells): 8 mm. 9 mm. 10 mm. 11 mm. 15 mm. 18 mm. wooden panels like Osb, Plywood etc.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* (OSB) WOOD

INSULATION PRODUCTS

* ROCKWOOL

EXTERIOR SURFACE COATINGS

*(OSB) WOOD

*FIBERCEMENT

*MAGNESIUM OXIDE

*PLASTERBOARD

OUR OSB-WOOD/PLASTERBOARD READYMADE WALLS (EPS-INSULATED)

• EPS Polystyrene is in the B2 fire class.

• Its heat conductivity value is 0.033 w/mK.(It depends on thickness of the core.)

• TSE-825 use temperature is between -50 ºC and 75 ºC.

• Densities 16, 18, 20, 24, 26, 28, 30 kg/m³

• Thicknesses of the insulation core (filler): 20 mm. 30 mm. 40 mm. 50 mm. 60 mm. 80 mm. 100 mm. 120 mm. 150 mm.

• Coating Thicknesses (shells):

8 mm. 9 mm. 10 mm. 11 mm. 15 mm. 18 mm. wooden panels like Osb, Plywood etc.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* PLASTERBOARD

INSULATION PRODUCTS

* EPS

EXTERIOR SURFACE COATINGS

*(OSB) WOOD

*FIBERCEMENT

*MAGNESIUM OXIDE

*PLASTERBOARD

OUR OSB-WOOD/PLASTERBOARD READYMADE WALLS (POLYURETHANE-INSULATED)

• Polyurethane is in the B2 fire class.

• Its heat conductivity value is 0.022 w/mK. (It depends on thickness of

the core.)

• TSE-825 use temperature is between -50 ºC and 75 ºC.

• Densities 38-40 kg/m³

• Thicknesses of the insulation core (filler): 20 mm. 30 mm. 40 mm.

50 mm. 60 mm. 80 mm. 100 mm. 120 mm. 150 mm.

• Coating Thicknesses (shells): 8 mm. 9 mm. 10 mm. 11 mm. 15 mm. 18 mm. wooden panels like Osb, Plywood etc.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* PLASTERBOARD

INSULATION PRODUCTS

* POLYURETHANE

EXTERIOR SURFACE COATINGS

*(OSB) WOOD

*FIBERCEMENT

*MAGNESIUM OXIDE

*PLASTERBOARD

Osb-Ahşap Hazır Duvar Sistemleri

Dış kabukları (ciltleri) ; OSB, tahta, kontraplak (plywood), sunta vb. gibi ahşap esaslı levhalardan oluşur.

Yalıtım çekirdeği; EPS (polistren), Taşyünü ve poliüretan gibi yalıtım malzemelerinden meydana gelir.

Ahşap sandwich paneller dış yüzleri ahşap esaslı levhalardan ve ortası ısı yalıtım malzemelerinden oluşan, bu sebeple de sıcağı ve soğuğu geçirmeyen fabrikasyon olarak üretilen yapı malzemeleridir.

TEKNİK ÖZELLİKLER

• Çevreye zararsız ve doğa dostudur.

• İşçilikten ve montaj süresinden tasarruf sağlar.

• Isı enerjisi kayıpları yalıtım malzemesi ve kalınlığına göre %80 ile %95 arasında ortadan kaldırır ve sıfır enerji kayıplı yapılar oluşturur.

• Daha sessiz ve ısı konforlu yapılar sunar.

• Isı transfer direnci (R-) çok yüksektir.

• Her türlü ahşap levha ile yapılabilir.

• Tek ve iki katlı binalarda ayrıca konstrüksiyon gerektirmez.

• Yalıtım çekirdekleri EPS, taşyünü ve poliüretan gibi ısı yalıtım malzemelerinden oluşur.

• R-35 ‘lik değerdeki panellerle yapılan bir yapıda ısı kayıplarının %96’sını önler.

• Yapısal ciltler (kabuklar); OSB, tahta, plywood, sunta vb. gibi ahşap esaslı levhalardan oluşur.

• Depreme karşı en iyi direnç gösteren yapı sistemidir.

• Sıcağı ve soğuğu asla geçirmez.

• Ürünlerimiz dünya SIP birliği standartlarına uygun üretilmektedir.