Fibercement Ready Wall

- Eps Hazır Duvar

- Poliüretan Hazır Duvar

- Taşyünü Hazır Duvar

- Tek Yön Alçıpan (Eps)

- Tek Yön Alçıpan (Poliüretan)

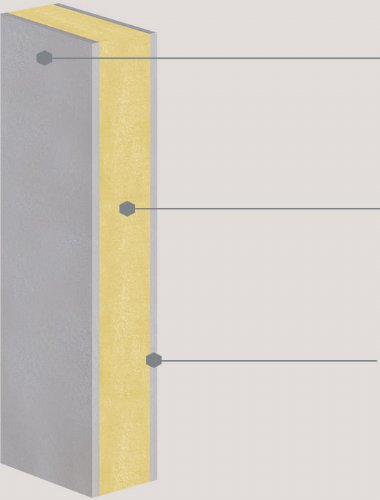

OUR FIBERCEMENT READYMADE WALLS (EPS-INSULATED)

• EPS Polystyrene is in the B2 fire class.

• Its heat conductivity value is 0.040 w/mK.(It depends on thickness of the core.)

• TSE-825 use temperature is between -50 ºC and 75 ºC.

• Densities 16, 18, 20, 24, 26, 28, 30 kg/m³

• Thicknesses of the insulation core (filler): 20 mm. 30 mm. 40 mm. 50 mm. 60 mm. 80 mm. 100 mm. 120 mm. 150 mm.

• Coating Thicknesses (shells):

6 mm. 8 mm. 10 mm. 12 mm. 14 mm. 16 mm. 18 mm. 20 mm. fiber cement boards.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* FIBERCEMENT

INSULATION PRODUCTS

* EPS

EXTERIOR SURFACE COATINGS

*FIBERCEMENT

*(OSB) WOOD

*MAGNESIUM OXIDE

*PLASTERBOARD

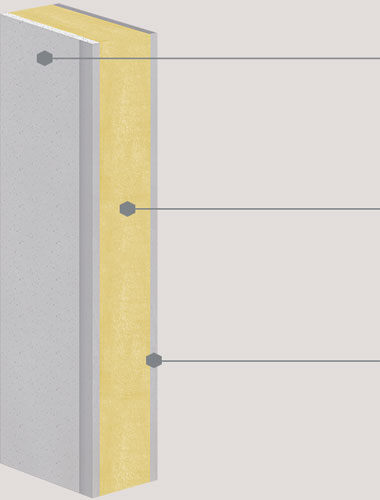

OUR FIBERCEMENT READYMADE WALLS (POLYURETHANE-INSULATED)

• Polyurethane is in the B2 fire class.

• Its heat conductivity value is 0.022 w/mK. (It depends on thickness of the core.)

• TSE-825 use temperature is between -50 ºC and 75 ºC.

• Densities 38-40 kg/m³

• Thicknesses of the insulation core (filler): 20 mm, 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm, 120 mm, 150 mm.

• Coating Thicknesses (shells): 6 mm. 8 mm. 10 mm. 12 mm. 14 mm. 16 mm. 18 mm. 20 mm. fiber cement boards.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* FIBERCEMENT

INSULATION PRODUCTS

* POLYURETHANE

EXTERIOR SURFACE COATINGS

*FIBERCEMENT

*(OSB) WOOD

*MAGNESIUM OXIDE

*PLASTERBOARDN

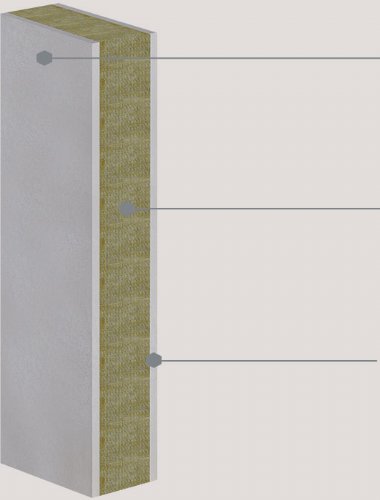

OUR FIBERCEMENT READYMADE WALLS (ROCKWOOL-INSULATED)

• Rockwool is used with the purpose of heat-sound insulation and fire insulation.

• Its heat conductivity value is 0.040 w/mK. (It depends on thickness of the core.)

• TSE-825 use temperature is between -50 ºC and +750 ºC.

• According to the German Norm DIN 4102 u TSEN 13501-1, it has the A class incombustibility.

• Densities 40-50-75-80-100-110-150 kg/m³

• Thicknesses of the insulation core (filler): 50 mm. 60 mm. 80 mm. 100 mm. 120 mm. 140 mm. 150 mm.

• Coating Thicknesses (shells): 6 mm. 8 mm. 10 mm. 12 mm. 14 mm. 16 mm. 18 mm. 20 mm. fiber cement boards.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* FIBERCEMENT

INSULATION PRODUCTS

* ROCKWOOL

EXTERIOR SURFACE COATINGS

*FIBERCEMENT

*(OSB) WOOD

*MAGNESIUM OXIDE

*PLASTERBOARD

OUR FIBERCEMENT/PLASTERBOARD READYMADE WALLS (EPS-INSULATED)

• EPS Polystyrene is in the B2 fire class.

• Its heat conductivity value is 0.040 w/mK.(It depends on thickness of the core.)

• TSE-825 use temperature is between -50 ºC and 75 ºC.

• Densities 16, 18, 20, 24, 26, 28, 30 kg/m³

• Thicknesses of the insulation core (filler): 20 mm. 30 mm. 40 mm. 50 mm. 60 mm. 80 mm. 100 mm. 120 mm. 150 mm.

• Coating Thicknesses (shells): 6 mm. 8 mm. 10 mm. 12 mm. 14 mm. 16 mm. 18 mm. 20 mm. fiber cement boards.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* PLASTERBOARD

INSULATION PRODUCTS

* EPS

EXTERIOR SURFACE COATINGS

*FIBERCEMENT

*(OSB) WOOD

*MAGNESIUM OXIDE

*PLASTERBOARD

OUR FIBERCEMENT/PLASTERBOARD READYMADE WALLS (POLYURETHANE-INSULATED)

• Polyurethane is in the B2 fire class.

• Its heat conductivity value is 0.022 w/mK. (It depends on thickness of the core.)

• TSE-825 use temperature is between -50 ºC and 75 ºC.

• Densities 38-40 kg/m³

• Thicknesses of the insulation core (filler): 20 mm, 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm, 120 mm, 150 mm.

• Coating Thicknesses (shells): 6 mm. 8 mm. 10 mm. 12 mm. 14 mm. 16 mm. 18 mm. 20 mm. fiber cement boards.

• Measures of panel: Width and height measures of sandwich panel are produced with respect to project.

INTERIOR SURFACE COATINGS

* PLASTERBOARD

INSULATION PRODUCTS

* POLYURETHANE

EXTERIOR SURFACE COATINGS

*FIBERCEMENT

*(OSB) WOOD

*MAGNESIUM OXIDE

*PLASTERBOARD

Fibercement Hazır Duvar Sistemleri

Termoduvar Yapısal İzoleli Paneller arasında yer allan bu yapı panelleri tamamen doğal malzemelerden üretilen FiberCement levhalar arasına farklı yalıtım çekirdekleri lamine ve enjekte edilerek üretilir.

TEKNİK ÖZELLİKLERİ

• Çevreye zararsız ve doğa dostudur.

• FiberCement sandwich paneller çevre dostu olup tamamen zararsız yapı ürünleridir.

• Bütün iklim kuşaklarında en çok tercih edilen ve suyu geçirmeyen bir yapı panelidir.

• Deniz suyu ve buharlarından etkilenmez.

• Yalıtım çekirdekleri projeye göre EPS,Poliüretan ve taşyünü gibi yalıtım malzemeleridir.

• Bünyesinde haşere barındırmaz,çürümez,asbest içermez

• FiberCement levhalar yanmaz.Sınıf olarak da A1 sınıfındadır.

•FiberCement kabuklar(ciltler)6,8,10,12,14,16,18,20 mm. kalınlıklarda kullanılabilir.

• Sandwich Panel Olarak Üretim Boyutları 625 mm x 2500 mm

625 mm x 3000 mm / 625 mm x 3500 mm

1250 mm x 2500 mm / 1250 mm x 3000 mm

• Dış yüzeylerinde ahşap desenli ya da taş,tuğla desenli FiberCement levhalarda kullanılabilir.

• Montaj sırasında özel metal ya da ahşap birleştirme elemanları tekniğine ve detayına uygun kullanılarak sandwich panellerin bina statiğinde mükemmel bir yük taşıma performansı sergiler.